|

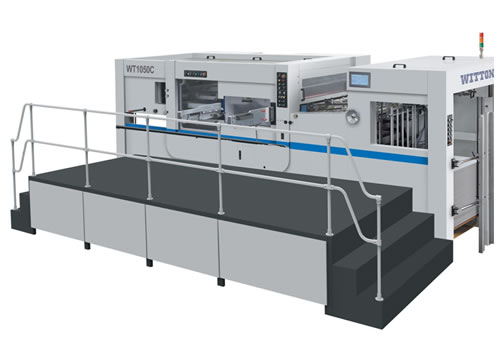

WT1050C fully automatic flat pressing and waste removal die cutting machine |

|

Features

★ Using high-speed paper feeder, it has high paper feeding precision, good stability, durability, quick adjustment, and is suitable for both thick and thin paper.

★ The paper-feeding wallboard is made of castings, which has good stability and is suitable for high speed.

★The overall adjustment structure of the paper feeding table flip frame: accurate, fast and stable.

★The paper feeding table is made of imported high-end stainless steel plate, which is beautiful and durable, with low resistance and smoother paper feeding.

★Imported thin paper conveying belt, strong and durable.

★The front and rear transmission wheels and shafts of the main chain of the tooth row are strengthened and enlarged to ensure rigid, high-speed and stable operation.

★ The paper pressing brush of the paper delivery part is externally equipped with an all-round adjustment mechanism, which facilitates and effectively adjusts the paper delivery structure.

★The paper delivery and blowing control system ensures that the thin paper can be effectively collected at high speed.

★Servo controlled ball screw automatic pressure regulating device.

★Dual oil circuit system ensures safe oil supply.

★ Main drive synchronous belt (vertical intermittent), equipped with overload torque controller.

★ Non-stop paper feeding, precoded paper pile and auxiliary paper delivery mechanism, shortening auxiliary time and improving work efficiency.

★Die-cutting plate frame and bottom plate mechanism, humanized design, fast and convenient to install and adjust plates. (Optional pre-installed replica rack)

★Front gauge, side gauge and paper feeder fine-tuning device make paper positioning more accurate.

★ Photoelectric level control of double sheets, crooked sheets and empty sheets to ensure accurate and stable paper and reduce waste.

★Touch screen human-machine interface, real-time dynamic monitoring and display of operating status, making machine adjustment and troubleshooting convenient and fast.

★Circulating cooling oil supply system ensures that the main moving parts of the machine are well lubricated and durable.

★Timing and quantitative oil supply system ensures that other moving parts of the machine are fully lubricated and has a long service life. |

|

| |

|

| |

| Machinery Products |

|

|

|

| Machinery Search |

|

|

|

| Contact us |

| WITTON CUTTING MACHINERY |

| ADD:Industrial Park,Zhenglou,Pingyang,Zhejiang Province,China. |

| TEL:0577-63787771 |

| FAX:0577-63785288 |

| Zip Code:325200 |

| Email:office@wittonchina.com sales@shmchina.net |

|

|